VENDOR MANAGEMENTIn 2023 we surveyed over 95% of our Tier-1 suppliers and over 85% of our Tier-2 suppliers in terms of expenditure value*.

Based on the information collected, we would like to highlight the following data concerning both Tier-1 and Tier -2 suppliers.

Among the Tier -1 suppliers interviewed, we are proud to share that:

• 63% already have policies in place aimed at reducing their environmental footprint

• 30% have green energy supply agreements

• 35% already have implemented circular material processes

• 81% have been working with us for more than 5 years, of which 36% for more than 10 years

Among the Tier-2 suppliers surveyed:

• 57% already have functioning policies in place aimed at reducing their environmental footprint

• 30% have green energy supply agreements

• 35% already have implemented circular material processes

• 85% have a business relationship with us since more than 5 years, of which 43% since more than 10 years.

Discover more about our Vendor Management system in our

Sustainability Report.

Our target is to have 55% of our suppliers (in value) having 50% of their energy supply with renewable sources within 2029.

RESPONSIBLE SOURCING & PREFERRED MATERIAL LISTIn 2022 Bally developed its Preferred Material List, a scientific tool created to help us to design sustainable products by better selecting the materials for our collections.

The list defines four levels of classification for each material according to its certification, and the associated traceability.

•

Preferred: Renewable | Recycled (pre- and post -consumer) | Regenerative | Organic | Bio-based | Low impact materials with sound and recognised supporting proofs

•

Good: Renewable | Recycled (pre- and post -consumer) | Regenerative | Organic | Bio-based | Low Impact materials with weaker supporting proofs | Traceable Conventional materials

•

Discouraged: Untraceable Conventional materials

•

Banned: Materials that do not fall under previous categories and are internationally limited or prohibited

Our target is for at least 90% of our materials to be classified as “preferred” or “good” by 2028; indeed, we consider as “sustainable” just the materials that can be classified as such.

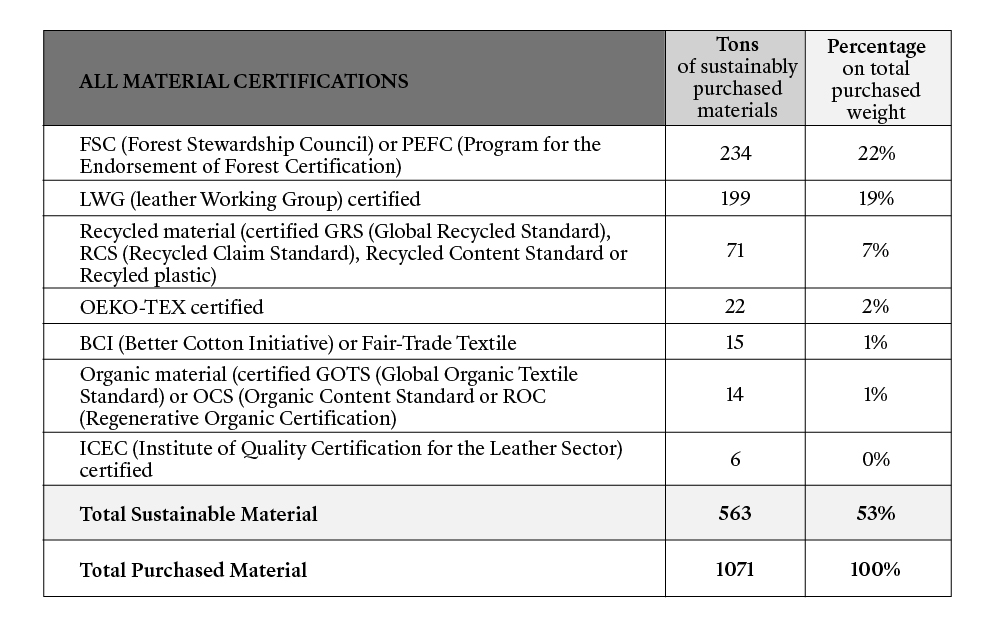

In 2023, 53% of our total weight of purchased material came from sustainable sources.